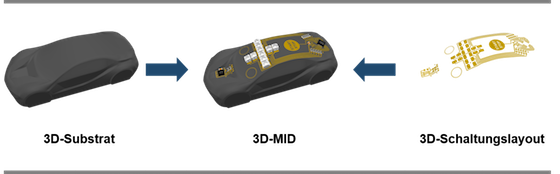

Spatial circuit carriers are experiencing a dynamic development, so that the resulting term Molded Interconnect Devices (MID) during the MID Congress 2010 was renamed to Mecha-tronic Integrated Devices. The original term reflected the integration of mechanical and electrical functions in injection molded threedimensional bodies. In this area the different MID technologies already have many applications in series products, especially as antennas in mobile devices like smartphones and tablets, mechatronic modules in motor vehicles and medical equipment.

On the other hand, there is the possibility through a multitude of new coating and printing processes to supply almost all types of carrier materials (e.g. duro- and thermoplastics, ceramics and metal cores) with a larger selection of functions. Besides mechanical, electrical, thermal, optical and lighting also sensor and actuator functions on spatial surfaces can be realized. The idea of cyberphysical objects that are small, intelligent and communicative mechatronic modules, can be realized with MID production technologies in an outstanding fashion. Due to the advantages

of MID, an increased degree of miniaturization, a high integration density as well as a shortening of the process chain can be realized.

In times of Internet of Things (IoT), cross-sector applications like sensory functions, electronic intelligence, energy storages and communication capabilities (e.g. antennas) have to be integrated in tightest installation spaces on any material. These boundary conditions with respect to the continuous further development of structuring, metallization and printing processes are the ideal growth medium for Mechatronic Integrated Devices.