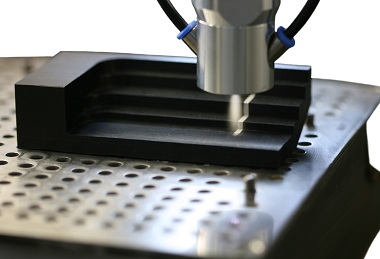

The plasmadust technology enables automated deposition of metallic structures from a cold-active, atmospheric pressure plasma directly onto injection moulded components. The plasma gas is generated by means of a highly effective, pulsed arcing gas discharge. The coating powder (grain diameter between 100 nm and 20 µm) is fed continuously to this cold, non-thermal plasma that has a temperature between 120 and 250 °C (depending on the nozzle) under ambient conditions. At the same time, specially developed atomizer/conveyor technology ensures that the incoming supply is agglomerate-free. Combined with an adjustable, even flow of particles, it is possible to produce homogeneous layers with a reproducible thickness. The process speed is up to 150 metres per minute.

Metallic structures, such as copper, silver, tin as well as metal alloys and mixed systems, can be applied with a thickness of between 1 and 1000 µm. The width of the conductive layer is also variable.

Separate activation of the synthetic surface which is necessary with many processes can be dispensed with when using plasmadust. The process can be controlled so that first of all the plasma jet activates the surface and then powder is fed in to coat it.

The inline-capable plasmadust technology reduces the process steps necessary for metallization and simplifies process control. This means, for example, that it is possible to dispense with galvanic processes or laser work steps for surface structuring. The process also has a good environmental life cycle assessment and energy balance since metallization takes place without the use of solvents (VOC-free), surface activation, cleaning and drying processes.