Additive manufacturing of dielectric elastomers for industrial use

Duration: 05/01/2022 – 04/30/2024

Research objective

The aim of the research project is to develop industrially scalable, additive manufacturing processes for dielectric elastomers and to create corresponding parameter guidelines. Existing manufacturing approaches must be optimised to the extent that they can meet the requirements of industrial application fields. In this way, it should be possible to achieve consistent system parameters with simultaneous design freedom, which will enable the use of modular electronic control elements. This lowers the entry barrier to this new technology. Furthermore, the system integration of mechatronic converters in the respective application scenarios is being researched and evaluated. This is illustrated by demonstrators of additively manufactured sensors and actuators, which form the basis for a new generation of soft, flexible sensors for use in human environments and compliant actuator solutions for the growing field of soft grippers and soft robots.

Description

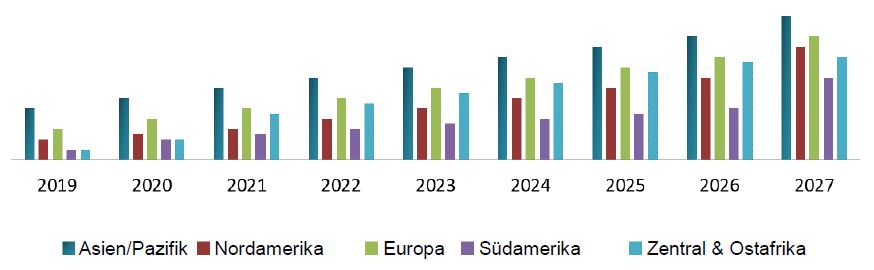

Due to its robustness, flexible integration, low weight and low production costs, the market for flexible electronics is continuously growing, as can be seen in Figure 1. Intuitive user interfaces and body-worn electronics from the consumer goods, automotive and healthcare sectors are the main application areas.

Figure: Flexible electronics market growth by region from 2019 to 2027 in USD million

Source: MAXIMIZE MARKET RESEARCH LTD. Global Flexible Electronics Market: Industry Analysis and Forecast (2019-2027). by Components, Application and by Geography, 03/2021

In the health sector, flexible sensor technology is often used to record vital data as part of prevention or diagnostics. By integrating them into clothing, watches and other sensors that adapt to the movement of the body, more data can be captured, contributing to more sophisticated, data-driven diagnostics. As a result, the market for flexible electronics in the health sector continues to grow at an annual rate of 8%. In addition, these applications are strengthened by the digitalisation initiatives of the federal government.

Another important driver for the positive market development is the Internet of Things (IoT). Through flexible electronics, surfaces, textiles or other materials can be functionalised and thus contribute to networking and interface provision. This creates new design possibilities for automotive and intuitive user interfaces that are discreetly integrated into the respective materials. The main players in this field are mainly composed of large companies such as Samsung Group, LG Group, Solar Frontier, First Solar or Panasonic. Through the technology development in the present research project, small and medium-sized enterprises (SMEs) based in Germany are to be enabled to enter this promising technology so that they can also benefit from the current trend technologies.

In the course of the project, however, not only the usability of flexible electronics for SMEs is addressed, but also their production. In this area, additive manufacturing, on which most processes for the production of flexible electronics are based, will be addressed. This sector has also experienced strong growth in the past decade, as the processes are no longer used for prototyping only, but also for manufacturing components. For SMEs, additive manufacturing offers clear advantages due to low acquisition costs and individual component production or small series production.

Economic relevance of the targeted research results for SMEs

The economic relevance results from the versatility of the DE, which can be specialised with regard to different applications by adapting their essential geometric parameters accordingly. Due to the flexibility, the small installation space and the low weight of the systems, new technologies are opened up, conventional sensor applications are substituted by integrative solutions and biomimetic drives are made possible.

The production of functional DE requires a sensible combination of different parameters and offers several possibilities with different manufacturing tolerances. By investigating the suitability of different processes and in particular their suitability for different applications, this project offers a broad-based feasibility analysis and enables small and medium-sized companies in particular to choose a targeted strategy and reduce failed attempts. This will be made possible for the companies involved in the project primarily through the guide for selecting suitable manufacturing processes and guidelines for system design, which will be produced at the end of the project.

Additive manufacturing processes can be used by SMEs in particular to produce prototypes and small series economically. In this context, the project offers the additional advantage of parametrically investigating the flexibility of dielectric elastomers with regard to their system characteristics. This allows application-related modifications to be implemented efficiently.

For equipment manufacturers such as Neotech AMT, an increasing demand in the area of flexible printed electronics can be expected. Ink material manufacturers for printed electronics such as GSB Wahl or LUH GmbH will also profit from this. Due to the required components of the control electrics, manufacturers for microelectronics such as Digalog gain an innovative edge through the project contents. SMEs from the medical technology sector (Movimento, HumanOptics) occupy pioneering roles in the context of digitalisation and thus gain a competitive advantage.

Finally, the results of the project enable SMEs to tap into new, future-oriented markets such as communication technologies for Industry 4.0 and IoT as well as components for medical technology, which form a central component for digitalisation in this area.

Research institutes

For further contact details, please contact the office. E-Mail to office

Friedrich-Alexander University Erlangen-Nuremberg

Institute for Factory Automation and Production Systems (FAPS)

Documents

Documents about the project are available in the members area.

If you are not a member yet, you will find information about membership here.

1) Project Meeting Presentation 07/22/2022