IGF-Project 21894 N: Digital printing of conductive inks by inkjet for miniaturization of electronic assemblies [DigiTIMe]

Due to the continuing trend towards miniaturization, function integration and increased component density, highly miniaturized components are becoming increasingly important. However, problems frequently arise with solder paste printing when processing the increasingly smaller components. Dirty or clogged stencils and poor release behavior of the solder paste due to unfavorable wall-surface ratios result in inadequate solder joints.

In the project “Digital printing of conductive inks by inkjet for miniaturization of electronic assemblies” DigiTIMe, an inkjet printing system (digital printing) on a high-precision two-axis kinematic system with height-adjustable print head for planar assemblies is being developed, which can alternatively print low-viscosity conductive adhesives or conductive inks by means of modular print heads in order to contact the smallest SMD components with classic printed circuit boards.

The approach envisages, on the one hand, the development of the SMT line-integratable printing system and, on the other hand, the evaluation of suitable printing media. Materials are being considered that are as harmless to health as possible,

as well as being easy to handle and capable of producing a conductive connection at temperatures below 300 °C. The materials must be suitable for this purpose.

Various inks and adhesives containing silver nanoparticles and microparticles are suitable as potential bonding media. Aqueous and organic-based media were selected for this purpose. These create a mechanical connection between the joining partners by means of sintering, thermal or UV-triggered setting and are compatible for printing with piezo or inkjet systems.

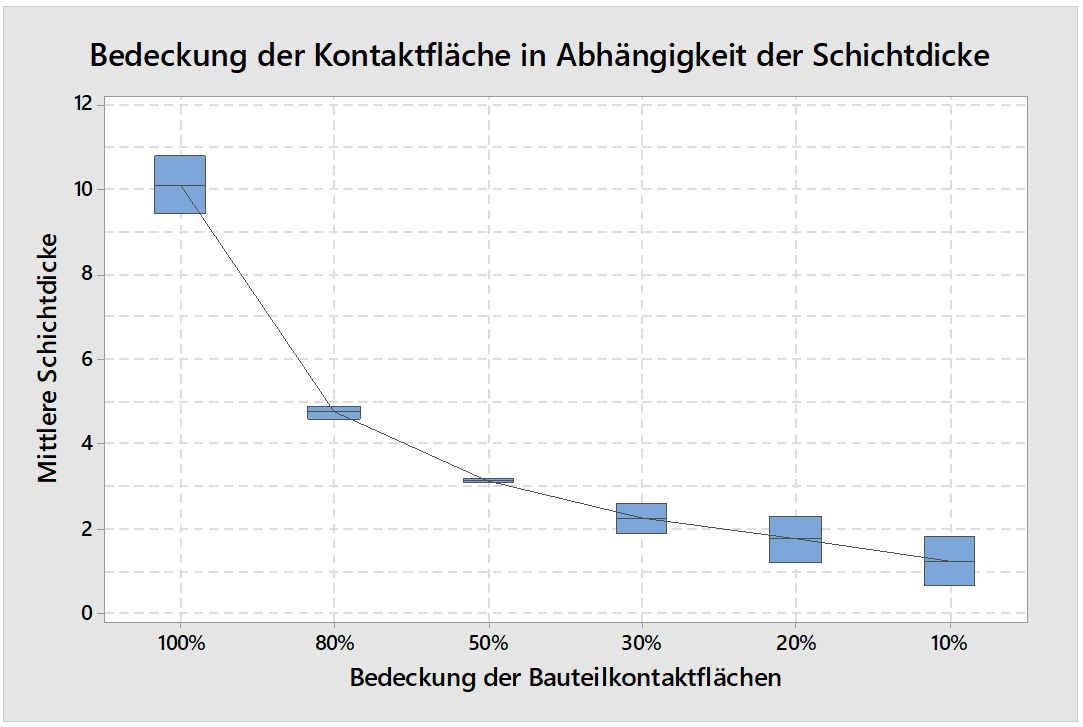

The electrical connection can be realized either by a sintered structure or anisotropic or isotropic conductive adhesive joints. The layer thickness and particle size required for this purpose were determined by considering the surfaces of both joining partners, as shown in Figure 1 and Figure 2 for a 0402m resistor. The resulting target size of the average layer thickness corresponds to 4.9 µm for contacting about 80 % of the pad and component contact areas.

Figure 1: Coverage of the contact area as a function of the coating thickness; Source: Chair of Manufacturing Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

Figure 2: Example of 80% pad coverage on an 0204m resistor; Source: Chair of Manufacturing Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

Since both isotropic and anisotropic conductive adhesive bonds are to be considered, both microparticle and nanoparticle suspensions are investigated.

The media are tested on a specially designed printed circuit board, which can be seen in Figure 3. This contains pads for devices of types 008004, 01005, 0603 as well as a QFN for evaluation of shadowed contact areas. The rest of the PCB design conforms to common industry standards.

The project is being carried out by the Chair of Manufacturing Automation and Production Systems (FAPS) at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU). On the industry side, the project is supported by the companies APAG Cosyst, ATN Automatisierungstechnik Niemeier GmbH, Robert Bosch GmbH, Fritsch SMT GmbH, InnoCoat GmbH, MSWtech, SEHO Systems GmbH, Neotech AMT GmbH, Sentinum GmbH, Siemens AG, Vierling GmbH and Zollner Elektronik AG.

The IGF project 21894 N of the Research Association Spatial Electronic Assemblies 3-D MID e.V. is funded by the Federal Ministry for Economic Affairs and Energy via the AiF within the framework of the program for the promotion of joint industrial research (IGF) based on a resolution of the German Bundestag.

Figure 3: Test PCB for device contacting using silver nanosuspensions and microsuspensions; Source: Chair of Manufacturing Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

Learn more about the DigiTIMe project here.