The Research Association 3-D MID is still looking for companies to accompany the project. If you are interested, please contact the office via phone (+49 911 5302-9100) or E-Mail (info@3d-mid.de). E-Mail to office

Description

Energy harvesting directly on the human body represents a current research trend for supplying energy to textile smart materials or wearables worn by people. Among other things, mechanical energy generated by the body through active or passive movements can be used as an energy source for this purpose.

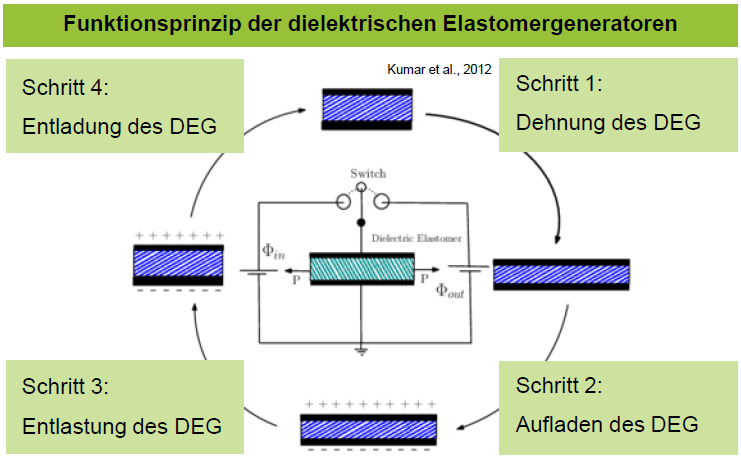

Dielectric elastomers (DE) have high potential for use as flexible harvesting materials. Their structure is similar to that of a flexible plate capacitor with highly flexible electrodes and a thin, insulating polymer film in between. By applying an external mechanical stress, a thickness reduction can be generated, which leads to a convergence of the two planar electrodes and, due to incompressibility, to an expansion in the electrode plane. This geometry change further leads to a capacitance change, which results in a usable voltage. The main advantages of DE are its low weight, low manufacturing costs, energy efficiency and high adaptability, also with regard to medical applications.

Figure 1: Functional principle of dielectric elastomer generators; Source: Chair of Factory Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

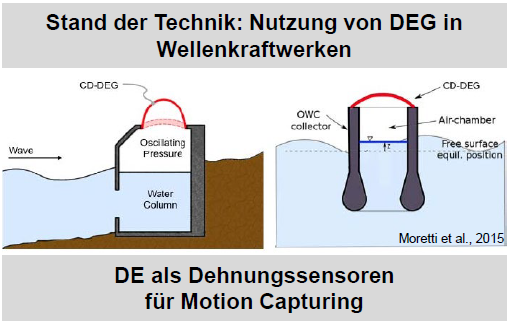

Figure 2: State of the art: use of DEG in wave power plants; Source: Chair of Factory Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

Flexible, DE-based harvesting systems have already been described as a research approach for technical applications, such as wave power plants. However, despite the great potential, the use for harvesting directly on the human body still offers a need for research. The aim of the project described here is to develop, manufacture and qualify flexible DE patches for energy harvesting on the body surface from kinetic energy. This can be done either by direct application to the skin surface or by insertion into textiles worn close to the body. Furthermore, it is planned to conduct a study to quantify the amount of energy that can be converted from different forms of movement and at different body sites.

Conceivable here is the use of passive movements, such as from the respiratory stroke, or active joint movements during walking or sports, e.g. at elbow or knee joints. By systematically varying patch geometry and layer thickness, design recommendations can be derived for the design of the harvesting patch as a function of the body site used, movement intensity and amount of energy that can be converted.

Screen printing or squeegee processes, which can be well automated, can be used to manufacture two-dimensional DE elements. A suitable process chain is to be further developed and optimized for the application within the scope of the project. The challenge here is, among other things, the evaluation of skin-compatible materials for the manufacturing process that are suitable for medical technology applications, as well as the system integration of the other electronic components required for voltage processing.

Research objective

The aim of the project is to qualify and optimize flexible, DE-based patches for energy harvesting directly on the human body from kinetic energy. On the basis of demonstrators and a later test person study, concrete design parameters of the DE patches (layer thickness, geometry) are to be varied and the convertible energy quantities are to be investigated at different body sites and as a function of the movement shape, in order to be able to derive design recommendations for future patch design. In addition, the further development and optimization of a suitable process chain with regard to medical technology applications is planned to enable the industrial use of harvesting patches for wearables or smart textiles.

Benefits and economic significance for SMEs

Due to the size of SMEs, they rarely have their own research and development department and are therefore often dependent on the know-how of external companies and partners. Through the pre-development within the project, the participating companies benefit directly from the project content and generate an innovative edge. The exemplary applications can additionally serve as a starting point and reference for further related applications.

Figure 3: DE-based applications; Source: Chair of Factory Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg

Research institutes

For further contact details, please contact the office. E-Mail to office

Friedrich-Alexander-University Erlangen-Nürnberg (FAU)

Institute for Factory Automation and Production Systems (FAPS)

You can find more project ideas here.